The most efficient & cost-effective precision farms on the planet.

- Delivered fully assembled and ready to use in a turn-key capacity. Setup only includes a few basic procedures with the equipment to convert from travel mode to production mode.

- Each machine includes several hundred square feet of space, lights, a water tank and everything needed to maintain plants.

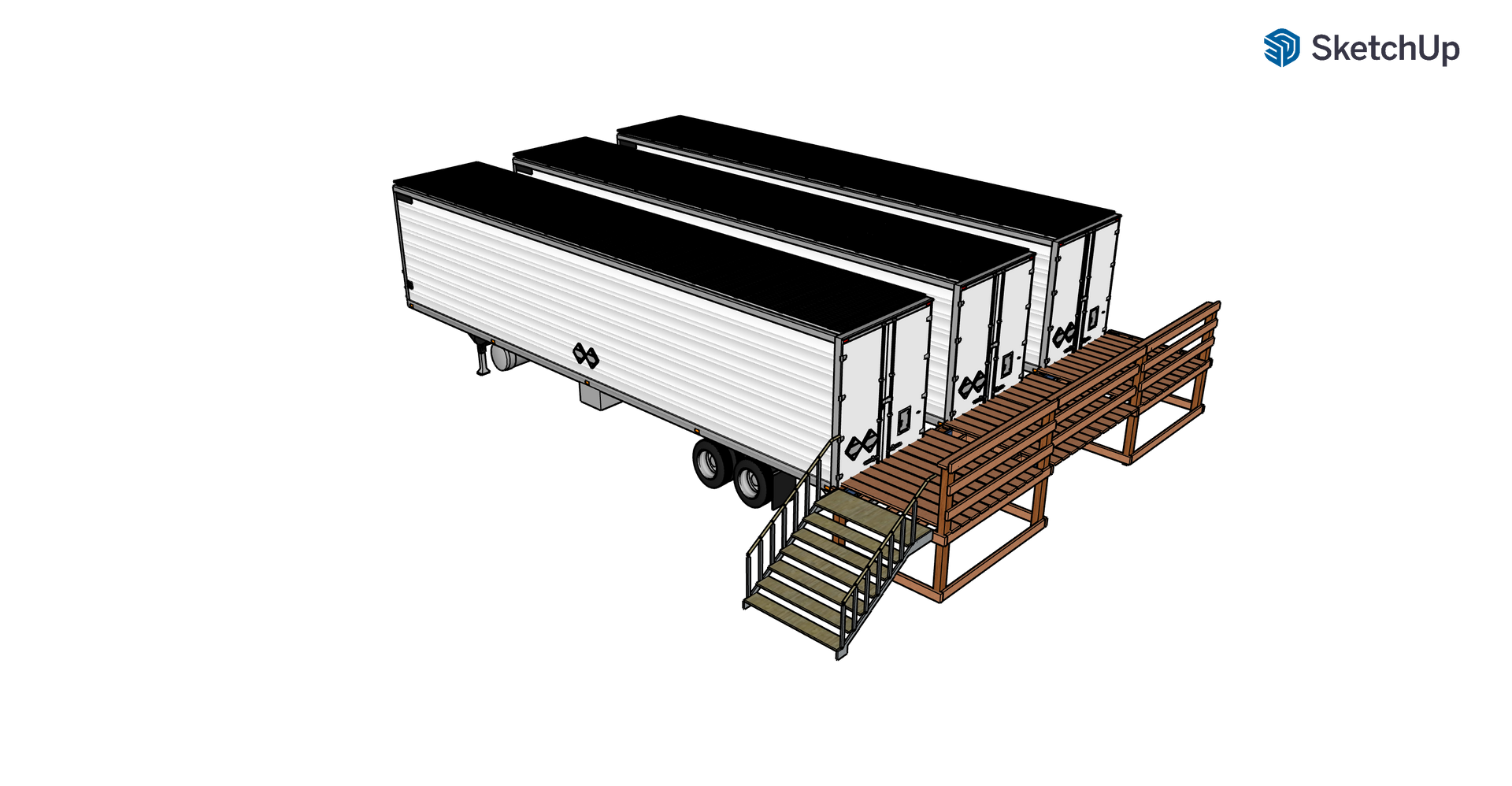

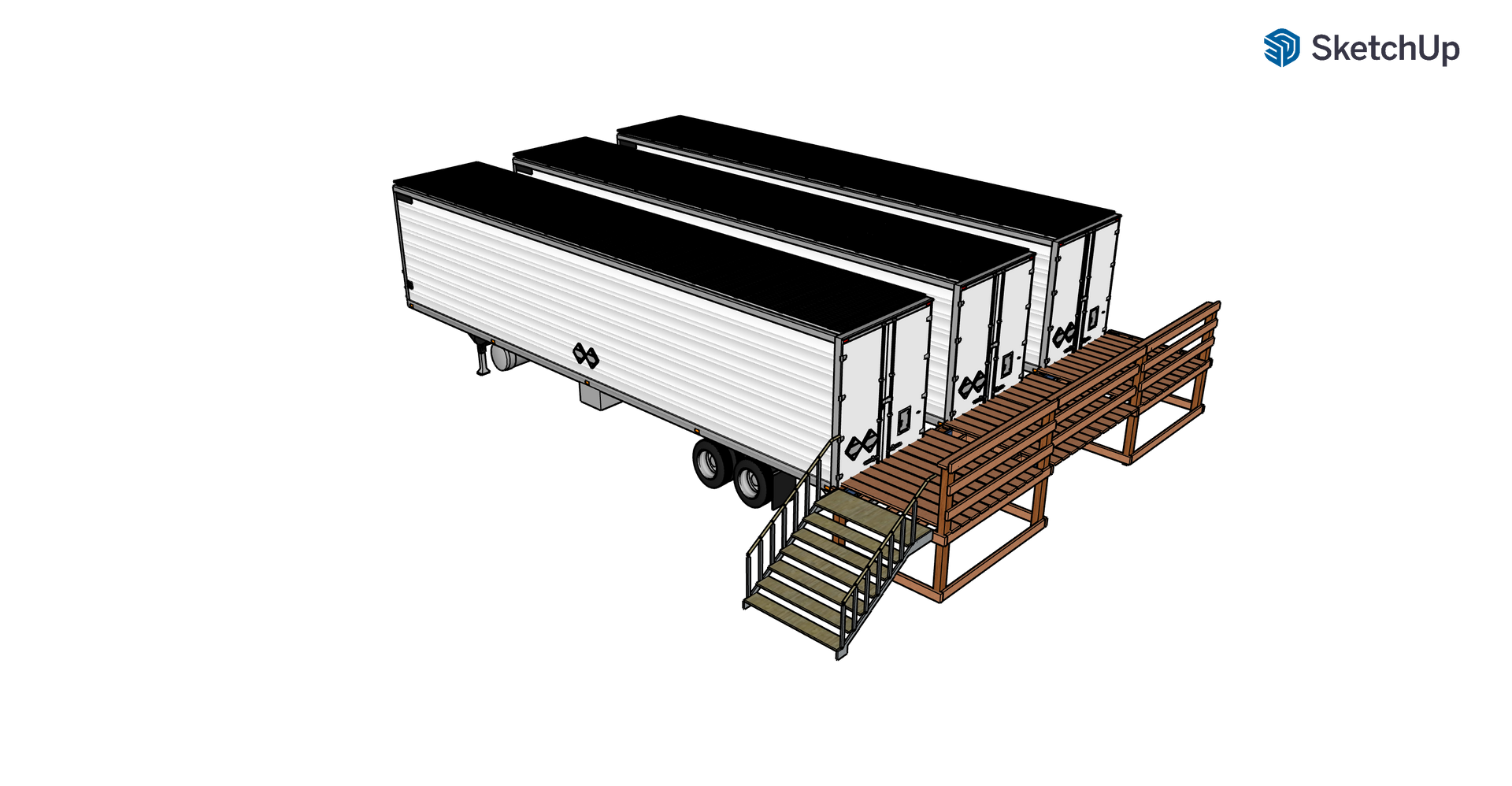

- Farms can also be scaled modularly by simply adding new units next to the existing ones.

- Solar Farms are designed and built to be used in any location around the world, regardless of the climate.

- Solar assisted - mounted on top of one to power all electrical inside two units

Seedling & Propagation Unit

Climate-controlled space, complete with everything involved in seedling and propagation work.

Space & Equipment for Propagation

A CleanTec Seedling & Propagation Unit model includes:

- Climate-controlled with overbuilt climate systems

- Adjustable height shelving space

- Self-draining floors

- 20+ square feet of working table space

- Sink with hot water

- Water storage tank

- High quality pumps for watering

Scalable & Easy-to-Use

Each system is scalable, so production can be scaled to meet demands. The equipment and processes are easy for anyone to use, regardless of existing plant propagation or growing knowledge.

Greenhouse Chamber Unit

Sealed, insulated & climate-controlled greenhouse chamber on wheels.

Sealed + Climate Controlled

Our Greenhouse Chamber model creates the perfect climate for mushrooms through innovative & efficient equipment to make the perfect space for growing plants.

Insulated + Easy to Clean

Regardless of the environment outside, plants will stay safe inside the unit with 3-5 inches of mold-resistant insulation & our innovative, overbuilt climate control system. Aluminum floors and plastic walls/ceiling make these units very easy to regularly clean.

Scalable & Easy-to-Use

Each system is scalable, so production can be scaled to meet demands. The equipment and processes are easy for anyone to use, regardless of existing plant propagation or growing knowledge.

Best Up-front & Operating Costs

Super Energy Efficient

100% of Equipment & Training Included

Delivered On-site with Hands-on Support

Why recycled Semi-trailers and not containers?

5 Main reasons

Ideal Starting Base

The inside of a refrigerated semi trailer is built to carry food, with mold-resistant aluminum floors and insulated, fiberglass-reinforced-plastic walls and roof, the interior makes the perfect base to grow mushrooms or plants inside.

Modular Design

While the inside of the units are a set design, they can be arranged in a modular fashion for easy expansion or special-use cases. This can also be a tactical advantage over time if you ever need to rearrange the farm setup.

No building permits

By law, because these are on wheels, our units are considered “machines” - which allow them to be placed on a property without having any approved building permits or inspections.

Semi trailers are in Surplus

There is a massive surplus of recyclable semi trailers with perfectly in-tact interiors that have been decommissioned from road use. Each of our units passes DOT inspection to ensure it’s safety before hitting the road for delivery.

Built to Last

While regular interior and exterior cleaning and equipment maintenance is required over time, these machines are built to last a lifetime. The exterior of the units along with equipment we use inside of the unit are carefully selected to withstand the elements, pushing our estimated lifespan for these units to over 50yrs. before they need a major renovation.